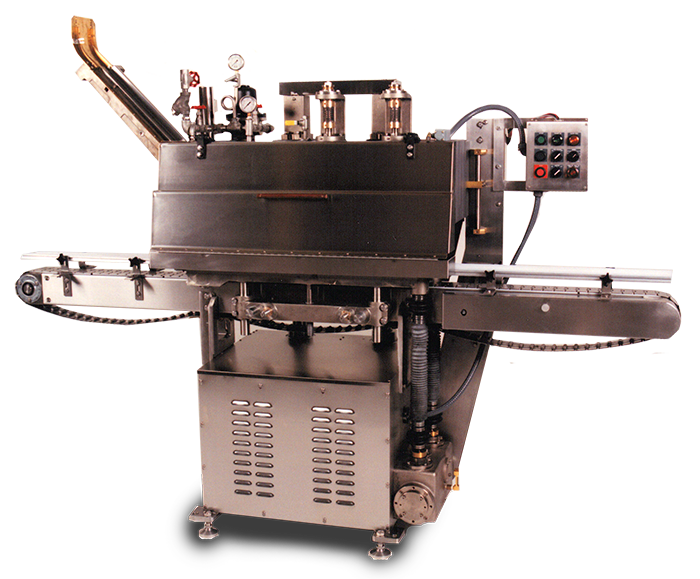

The Diversified Capping Equipment, now Dillin Capping Systems, Model 76-450 In-Line Steam Vacuum Capper is designed to apply lug caps, twist-off, or push-on caps to glass containers. Filled containers pass through the capper on a conveyor that is integral to the capper. Non-marking side belts grip the containers. The leading edge of the container pulls a cap from the cap feed chute as it is conveyed. After the cap is picked up, the container travels forward under the cap leveling plate, where it is leveled and simultaneously turned to engage in the first thread. The container then passes under a pair of cap tightening belts for final tightening.