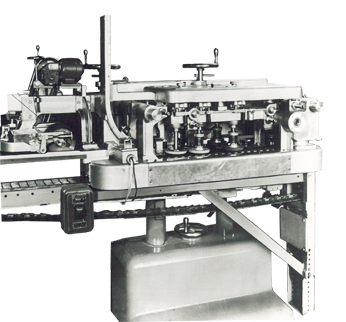

The Diversified Capping Equipment, now Dillin Capping Systems, Model 56-300 Rebuild Spin Capper is designed to apply continuous thread or lug caps to glass containers and some plastic containers, provided the plastic is rigid enough to resist collapsing with the side chain pads pressure applied. Filled containers pass through the capper on a conveyor that can also be provided by Dillin. Non-marking side chain pads grip the containers. The leading edge of the container pulls a cap from the cap feed chute as it is conveyed. After the cap is picked up, the container travels forward under the cap leveling plate, where it is leveled and simultaneously spun on finger-tip tight by means of a pair of primary cap starting rolls. The container then passes through two more pairs of cap tightening rolls, both clutch controlled, for final tightening.